Do you want to know how to start your belt conveyor? Are you experiencing a startup malfunction?

You are at the right place. Let’s take a look at the steps to start-up your belt conveyor correctly.

Before starting.

Starting a belt conveyor is very easy. No skills are required. Howewer, it is important to follow a few recommendations before starting up for the safely of the operators and to avoid damaging your equipment:

- Make sure that one is working on the conveyor or is near to the driving parts of the conveyor (rollers).

- Make sure your power supply is a 400V 3-phase without neutral.

- Check that the drum motor is clean and not covered in product.

- Ensure that all rollers are present, clean and free of dirt.

Tutorial video: starting a 6m-14m belt conveyor.

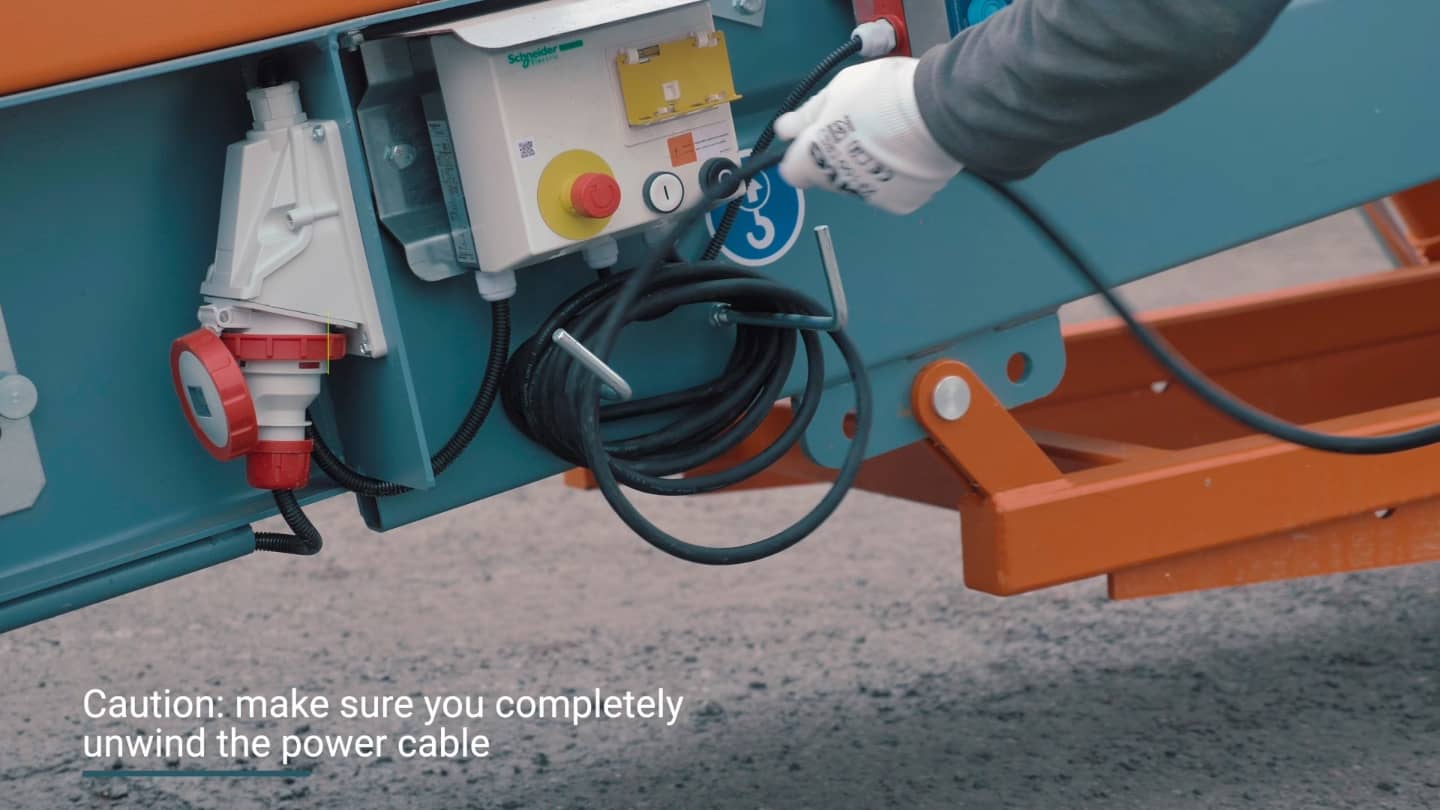

Step 1: turn on the power.

- Make sure you completely unwind the power cable.

- Plug the 4-pin industrial plug.

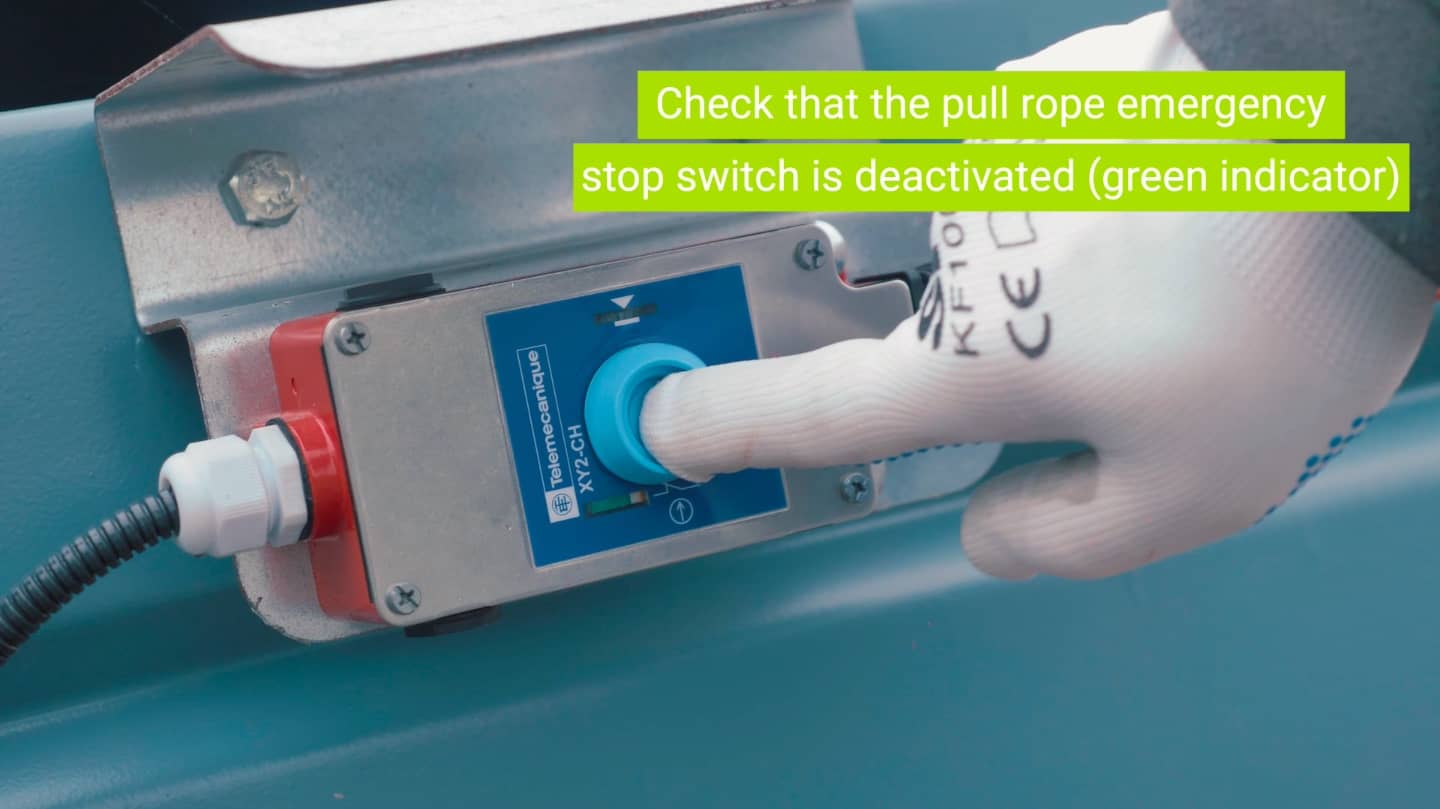

Step 2: disable the emergency stop buttons.

- Deactivate the mushroom emergency stop.

- Check that the pull rope emergency stop switch is deactivated (green indicator).

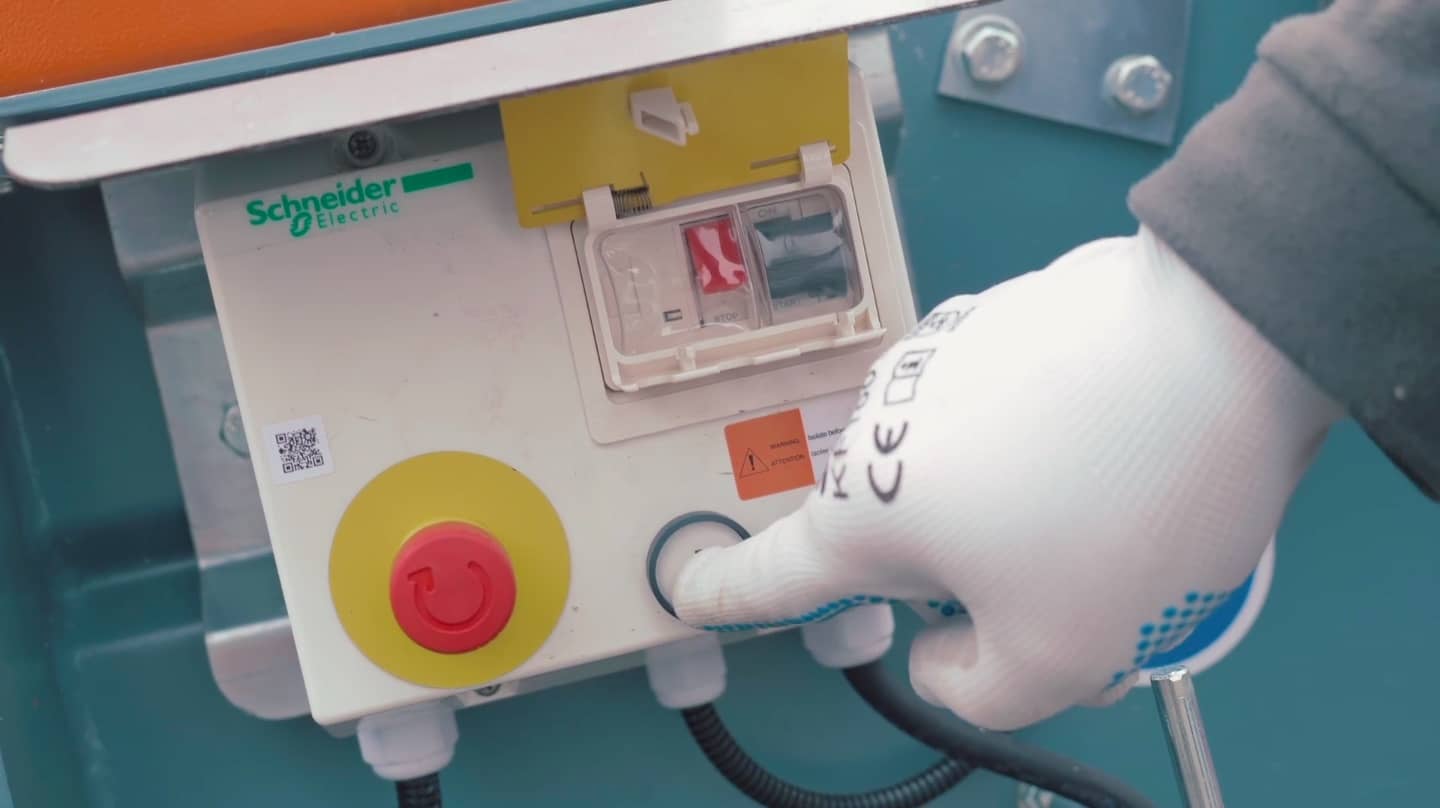

Step 3: start the belt conveyor.

- Push the black button under the safety lid.

- Press the “on” button on the belt conveyor (white button).

Your conveyor belt is up and running and ready to handle your bulk products !

The difficulties you may encounter.

The black button under the safety lid won’t operate.

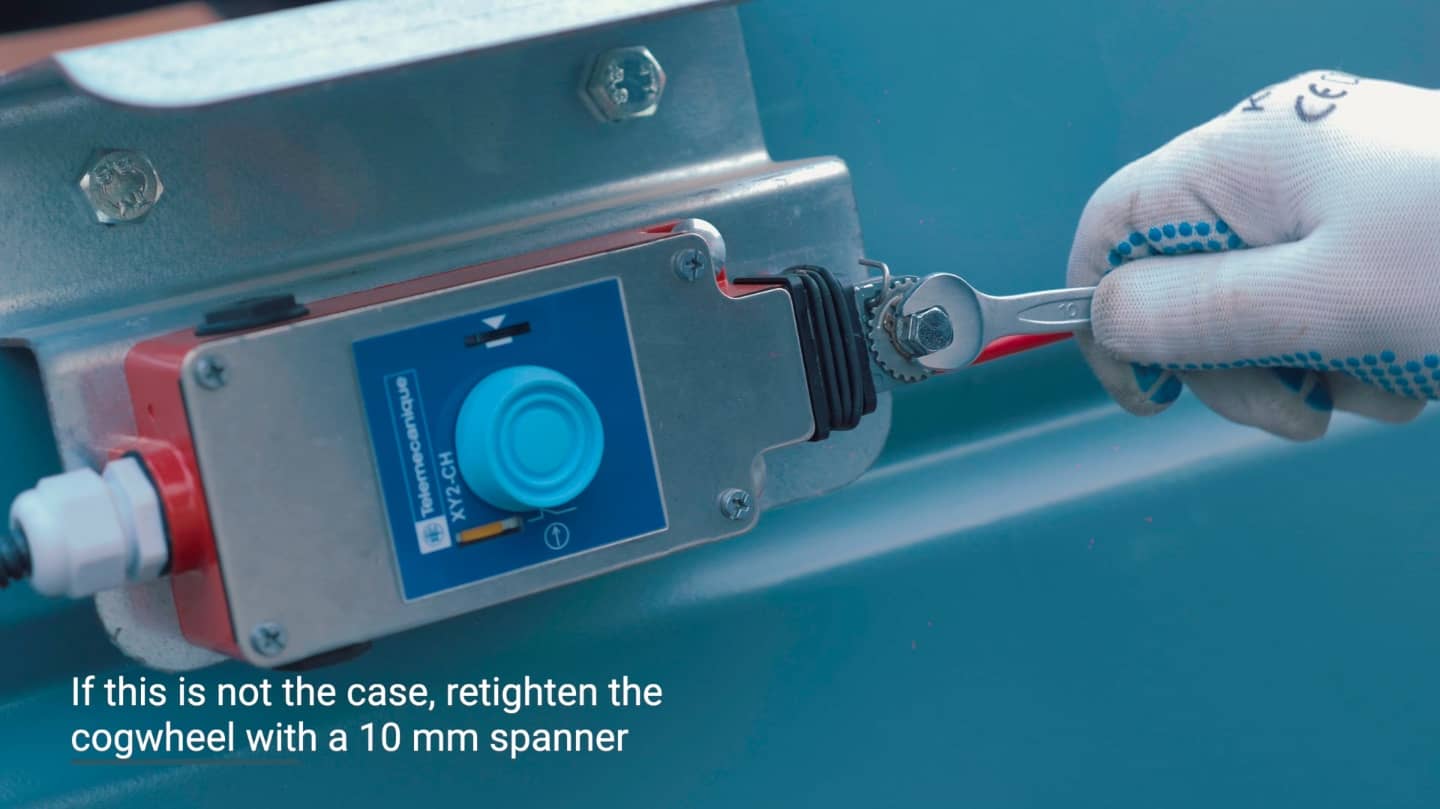

EQUIPMENT REQUIRED: 10mm spanner.

When starting up your belt conveyor (step 3), it is possible that the black button under the safety lid won’t operate. There are two possible reasons for this: the emergency stops are not properly deactivated and/or the tension of the emergency stop cable is not ok.

The steps:

- Check that the emergency stop buttons are disabled.

- Make sure that the tension of the cable is OK. To do this, check that the pointer in the adjustment area is within the while horizontal line. If this not the case, retighten the cogwheel with a 10mm spanner.

- Press the black button under the safety lid of the control box and then press the “on” button. The belt conveyor works !

The conveyor belt does not move in the right direction.

EQUIPEMENT REQUIRED: flat screwdriver.

If the belt conveyor does not move in the right direction, the direction of rotation of the motor drum must be reversed. This is easy to do, it is all done at the 4-pin industrial plug.

The 4-pin industrial plug supplied with the belt conveyor is equipped with a phase reverser.

The steps:

- Disconnect the 4-pin plug.

- With a flat screwdriver, reverse the 2 phases.

- Connect the 4-pin plug.

- Check that the emergency stop buttons are disabled.

- Push the black button under the safely lid and press the “on” button on the belt conveyor (white button).

The belt conveyor move in the right direction !

The motor drum of the belt conveyor does not start.

- Check that your power supply is a 400V 3-phase without neutral.

- Make sure that the plug is correctly connected.

- Check the connections inside the plug.

- Check that the power cable is not damaged.

- Check that the 2 emergency stops are deactivated.

Still having problems? We are at your disposal to help you. Contact ou technical service by sending and email to [email protected] or by phone at +33362658262.