Express delivery of 5 site conveyors for the needs of Demathieu Bard.

Launched in 2016, the modernisation and restructuring work at Saint Denis railway station is on an unprecedented scale. The largest SNCF railway station development project, the work is being carried out to make it easier for passengers to get around, particularly people with reduced mobility. The project includes the construction of an underground passageway under the rails, the raising of platforms by 40 cm and the creation of new infrastructure.

For our customer, the Demathieu Bard group, the project’s representative, the challenge was as great as the project itself: to maintain the station’s activity throughout the work and to meet the tight deadlines so as not to impact rail traffic.

A challenge to which we contributed by delivering 5 construction site conveyors for the transport of soil and cement gravel within a tight deadline.

Customer context.

At the beginning of May 2021, the raising of the platforms began, one after the other, in order to facilitate full access to the trains. To carry out the operation, several tons of earth and cement gravel must be transported to the platforms. Given the configuration of the site, the only way for DEMATHIEU BARD to get the bulk materials to their destination is through the underground passage and its access doors to the platforms.

Customer needs.

An express request for several site conveyors to catch up the delay.

The construction schedule is tight and the environment particularly constraining. The work on the platforms takes place exclusively at weekends, as this is the only time when some railways can be closed to traffic without disrupting traffic. Anything that cannot be done at the weekend therefore has a direct impact on the schedule.

DEMATHIEU BARD approached us at the end of May. Our mission: to find a simple and efficient solution, available immediately and taking better account of the constraints of the site

It should be noted that the doors of the subway allowing passengers to access the platforms were not identical and more or less finished. The conveying distance and/or the height to be crossed in order to convey the materials to the platforms could therefore differ from one platform to another.

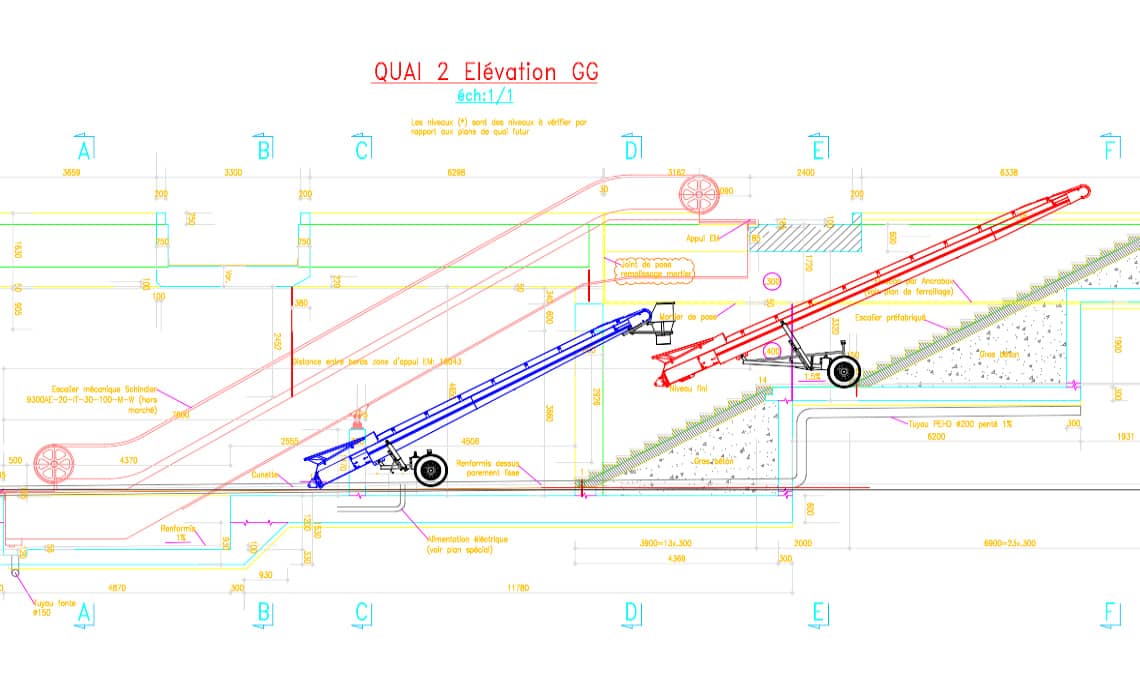

We therefore carried out an in-depth study of our customer’s needs by providing drawings and a personalised offer. After the quotation was sent and accepted by the customer, 2 construction conveyors were delivered. The combination of an 8M and a 10M conveyors proved to be the best option for conveying the bulk material to platforms 2 and 3.

Each conveyor delivered was equipped with a round hopper to facilitate bucket feeding. Delivered ready for use on a Friday, the conveyors could be used immediately the following day. In total, only 72 hours elapsed between the first contact with the customer and delivery to the site.

3 more construction belt conveyors in the following weeks.

Entirely satisfied with the performance of our equipment during the first weekend of use, the company DEMATHIEU BARD wished to rent us the following week 2 other conveyors: one of 10M and another of 6M. Finally, a few days later, it was the turn of a fifth conveyor with a length of 21M to be delivered.

While the use of an 8M and a 10M conveyor was the most appropriate and efficient combination for conveying earth and cement gravel to platforms 2 & 3, it was necessary to use two 10M conveyors for platforms 4 & 5. The role of the 6m bulding site conveyor, placed at the end of the process, was to transport the bulk materials a few metres further.

The original requirement for the 21M belt conveyor was slightly different. In order to raise platform 1, there was no direct access from the subway to handle the cement gravel to the desired location. We therefore proposed to our client to go directly over the subway. This was made possible by our 21m long conveyor.

For 2 months, our conveyors have enabled DEMATHIEU BARD to save time and to have reliable and secure equipment available that adapts to the constraints of the site.

Details of our response to customer needs.

All the conveyors that were made available to the client came from our stock managed at a carrier. It is this asset that enabled us to meet DEMATHIEU BARD’s urgent need in less than 72 hours.

Another advantage is that our conveyors with a length of between 6M and 14M are delivered fully assembled on a flatbed truck. As soon as they arrive, you can simply plug them in and start using them.

In contrast, due to the size of the machine, the 21M conveyor had to be assembled on delivery. A day of assembly and a suitable crane were required. The operation was carried out by DEMATHIEU BARD’s teams, at the customer’s request.

We have different types of site conveyors that can be adapted to your needs and constraints. Do not hesitate to contact us via our contact form or by phone for any information request. We are at your disposal.