Customer presentation.

The client is a French company specialising in goods carrier with a turnover of 7€ millions.

Context and challenges.

The haulage company collects and stores cereals for an agricultural trading company. To respect this contract, the company needed a solution for quickly receiving and storing large quantities of cereals in its warehouses, which have a capacity of 6,000 tonnes.

This involved a number of challenges:

👉Maximising the storage capacity of the warehouses.

👉Limiting handling of cereals to improve efficiency.

👉Reducing waiting time and truck downtime to speed up truck rotation.

To meet these challenges, our customer was looking for a high-performance, easy-to-handle solution able to create high cereal piles.

Our solution.

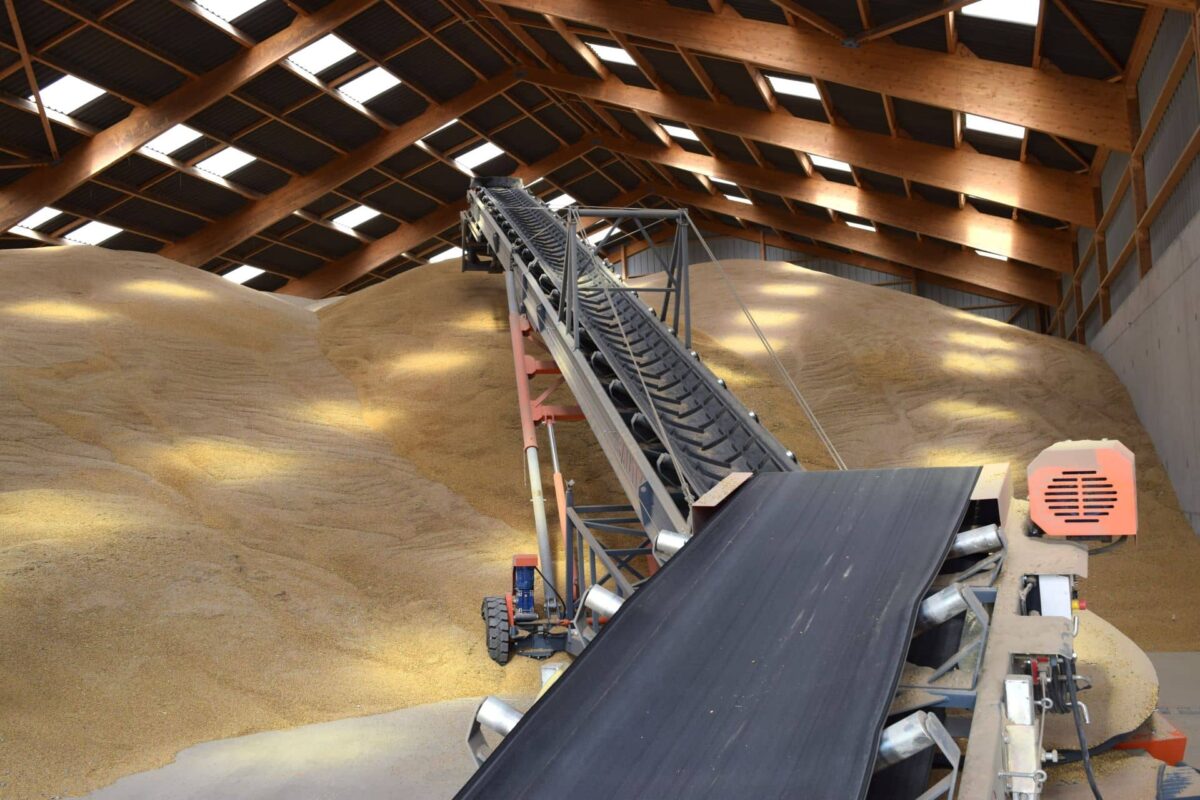

To meet the haulage company’s challenges, we proposed a mobile conveyor solution specially adapted to the transfer and storage of cereals on the ground. This solution combines a 7m truck unloader and an 18m agricultural belt conveyor.

The truck has an unloading hopper measuring 2.70 m x 0.97 m, which simplifies manoeuvres and the unloading of cereal skips.

The belt conveyor is designed to store cereals at a height of 7m, with an angle of inclination of 25°. The belt conveyor is equipped with:

- A 2m hydraulically adjustable and retractable projector, which ensures even distribution of the cereals inside the storage building.

- A rubber belt with 32mm high chevrons for efficient transport of all types of grain.

- Motorised pivoting wheels for optimum manoeuvrability.

- The whole unit is electrically powered and can be controlled remotely.

Installation.

The belt conveyor was delivered partially assembled on a flatbed truck. A few hours of assembly on the customer’s site were enough to make the belt conveyor operational.

We went on site to supervise the installation, check that the equipment was working correctly and train the users. The truck unloader was delivered assembled and ready for use after a simple plug-in.

Benefits and results.

✅The pile height has been increased by 2m compared to previous years. The mobility of the agricultural belt conveyor combined with the adjustable projector offers real comfort of use. The unloading and transfer of cereals is maintained without interruption.

✅Only 20 minutes are enough to unload and store 30 tons of cereals. With this time saving, our client can receive cereals from 20 to 25 trucks per day as quickly as possible.

A solution that has allowed our client to streamline its operations, accelerate its rotations and meet the challenges of its contract.