Evacuation of rubble with a belt conveyor in a tight environment: the Monegasque example.

To evacuate rubble and other bulk materials from construction sites, the use of traditional heavy plant machinery is generally the preferred method. However, there are other modular and efficient alternatives! This is the case with conveyor belts, the option chosen by our client SITREN, a subsidiary of the EIFFAGE group, for the Ecrin de Malachite project in Monaco.

Presentation of construction site.

Creation of a real estate complex on the cliff-side in the heart of Monaco.

Introduced in February 2021, the project consists of the creation of real estate complex on 11 levels for residential use, including 3 very high standing villas for private use and a building of 8 flats for collective use. The total area of the project is around 10,000m2 !

The important steps of the construction site are numerous. Among them, we can mention the levelling work and the creation of galleries. Works requiring mass removal of excavated material.

The challenges of the project.

Easy and safe evacuation of 28,000m3 of rubble.

To carry out the project, a part of the cliff must be destroyed. During the first months of the project, the rocks and other crushed material were evacuated thanks to a road next to the site. Over the months, the construction site was lowered below the level of the road, making it no longer possible to load the skip with a bucket. An alternative solution had to be found.

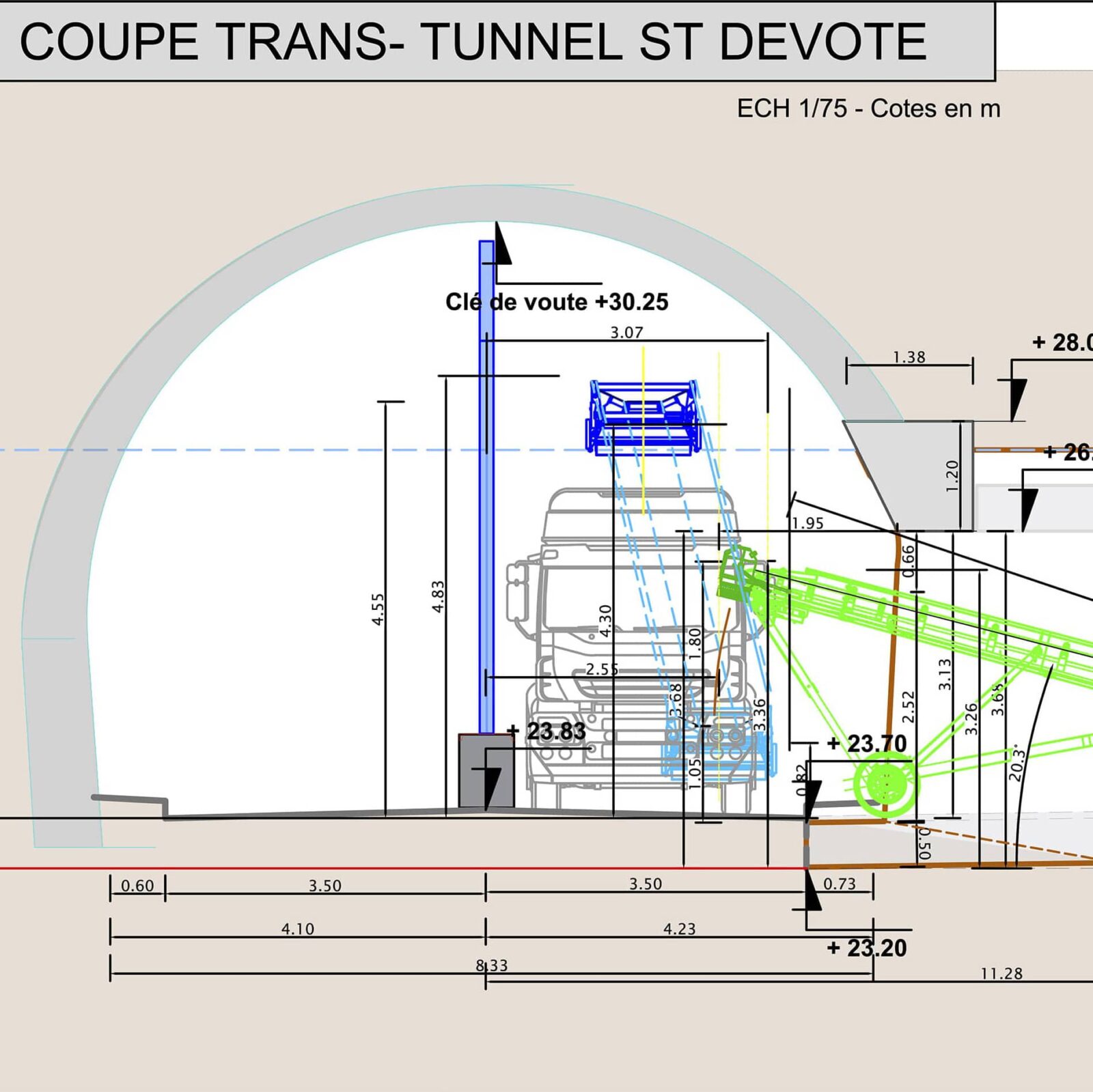

At the end of 2021, a raise boring shaft with a diameter of 2,40 was dug. From the construction site, it allows the rubble to be evacuated 40m below, directly into a road tunnel.

The need of the SITREN teams.

To evacuate the materials in a narrow area.

The area where the rubble was collected is narrow. It does not allow for efficient and safe evacuation and filling of trucks. The rubble is received in a gallery adjacent to a tunnel with one of the two lanes open to traffic. The constraints are numerous:

- The height of the gallery does not exceed 2,70m.

- The space for loading the skips is the width of one lane.

- The tunnel, in the form of a keystone, does not make it easy to fill skips at a height of 3m.

In this context, , it is difficult for the construction teams to evacuate the materials without multiplying the handling operations. This operation would undoubtedly have taken a lot of time with the risk of slowing down the construction site. It was therefore necessary to set up a simple and secure system for the evacuation of rubble.

The proposed solution.

A construction belt conveyor in the gallery and an another suspended from the tunnel!

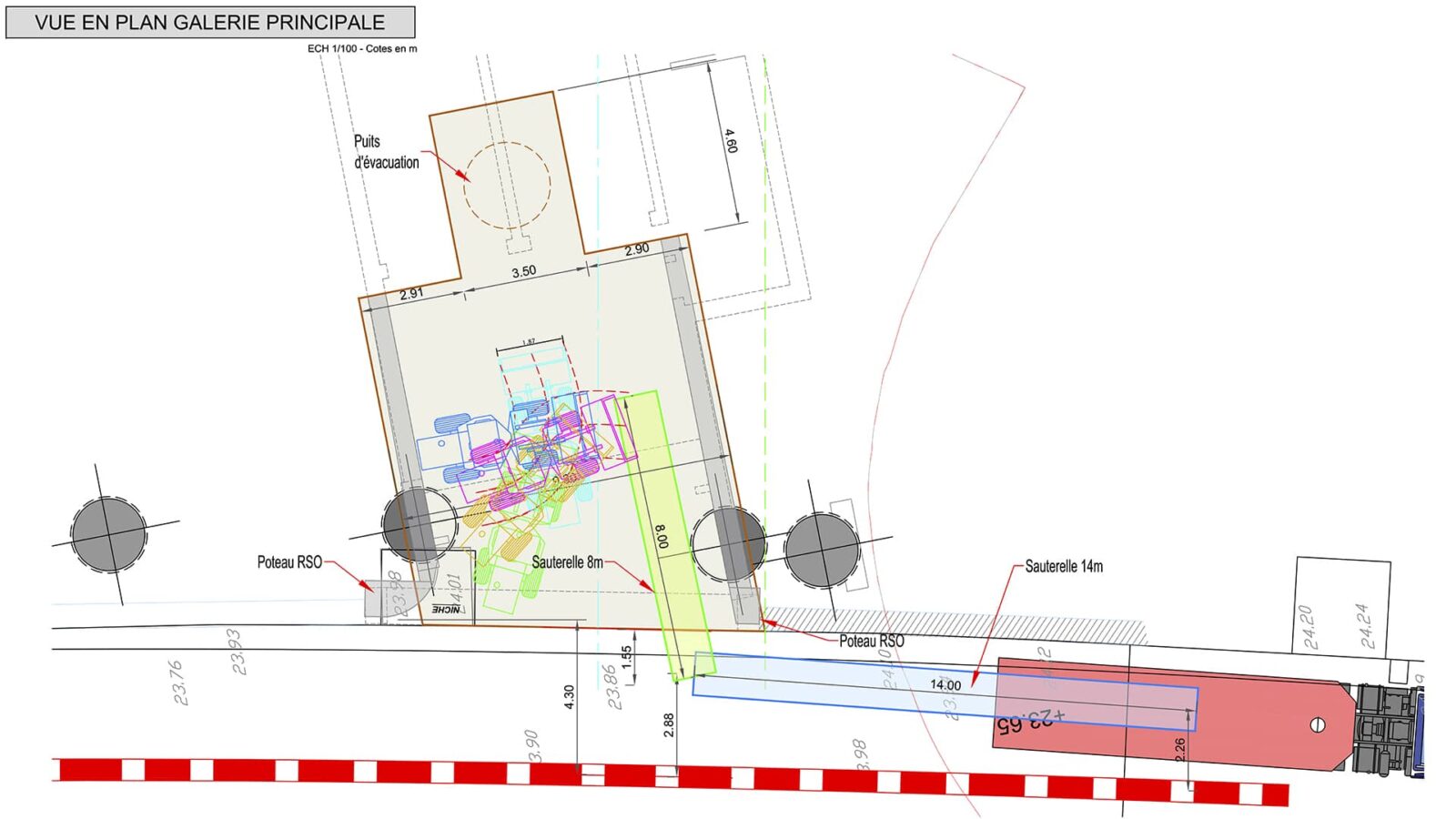

In collaboration with the SITREN teams, we studied and carried out several simulations until we obtained the best compromise: placed an 8m construction belt conveyor in the gallery and suspending a 14m conveyor from the tunnel!

In this configuration, the customer can continuously evacuate the rubble from the gallery with a simple mini-excavator. The 8m construction belt conveyor takes the rubble from the gallery and feeds it to the hanging conveyor. The hanging conveyor fills all the skips, allowing the drivers to back up under the conveyor. By moving forward gradually, the drivers can distribute the rubble in the skip.

Mobility, modularity and simplicity: elements that appealed to our client.

The site conveyors, like the other equipment, are mobile and can therefore be moved at any time. This mobility allowed the site teams to place the 8m conveyor in the gallery without difficulty. To facilitate bucket feeding, the conveyor was supplied with a round hopper.

When it comes to hanging equipment, mobility is no longer necessary. Fortunately, the simple removal of the lower part of the frame and the integrated lifting rings (with centre of gravity indicator) allowed customer to adapt quickly to the constraints imposed by the tunnel. No difficulties were mentioned by the teams.

Finally, the equipment was delivered ready to use. No assembly was required. A significant time saving for the customer. The clarity of the instructions (aided by the ease of use of the equipment) enabled the operators to understand the operation and start-up of the conveyors.

The benefits for SITREN.

Fast and safe disposal of excavated material.

During a visit the construction site, the SITREN teams were full of praise for the equipment: “simple equipment”, “reliable equipment”.

In just 15-20 minutes, the client can safely load 44 tonnes of rubble.

Benefits far from the first preconceptions! Accustomed to traditional equipment, the workers on the site shared their first impressions with us: “When we saw your equipment arrive, we didn’t believe it! We didn’t see a solution but rather a new problem. Eventually, it’s great!“

A powerful solution that should facilitate the work of the SITREN teams for a few more months. We wish them every success.